Engineering

Each production plant has a ‘critical path’ which decisively influences the qualitative and quantitative overall performance. Regardless of whether it is a new installation, a conversion or an upgrade, we have always focused on these crucial details.

Plant Layout

Technical and commercial layout or upgrade as desired – our customers define their targets – we develop the suitable hard- and software solutions to achieve our common goals.

Conversion and Modernization

Just-in-time modification of existing production lines or specific components within a fixed time frame – tailored to our customers’ needs.

To avoid longer down times in production we provide timed delivery and installation in line with our customers needs and thereby reduce the production losses to a minimum – if necessary as well using shift operation.

Upgrades and Performance Improvement

Improving product quality or production output in gypsum plants of any kind.

Our customers define their targets for higher quality or output. Gyptech will find the appropriate technical solutions and translate these step by step into reality – on from the first layout until final production restart.

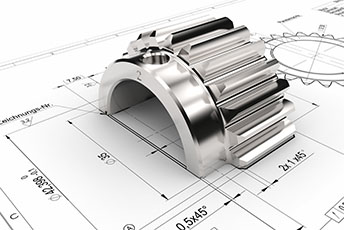

3D-Design

Utilizing INVENTOR 3D enables us to visualize the necessary installation and handling space starting from the first layout drawing. The graphical presentation of new machinery or components within an already existing production area shows all future changes for handling and maintenance already in the early design stages.

Detailed Design

Design of all components – down to the smallest screw and all required control elements – gives us the full control of all manufacturing steps and later on lifetime maintenance.

Fabrication Flow

Based on our detailed design work we will select the best possible fabrication method and parts required for all machinery and functional components. The manufacturers we select will be under close control for all steps of local fabrication.

Technical Acceptance

Fabrication based on our own design will undergo an acceptance procedure at the manufacturing place as well as purchased machinery and components. The final mechanical and electrical function and quality checks prior to startup will follow at the customer’s site – practically hand in hand with the training of the dedicated maintenance staff.

Functional Acceptance

Before the production line or component is officially handed over to the customer, all projected performance and quality parameter will be verified and documented on site.

The final acceptance document ensures the contractual obligations for both sides and guarantees the long-term high availability and reliability of all machinery and components.

Contact

Jürgen Seliger

Contact for Engineering-Services

Tel.: +49 (0)8431 5387-0

E-mail: jseliger@gyptech.de